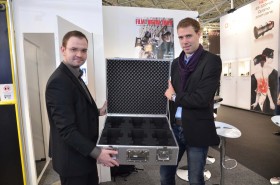

I met Cocoon’s Maik Finzel and Patrick Biesinger at IBC. Cocoon makes terrific custom foam interiors for camera and equipment cases. For example, their products have coddled Compact Prime and Master Prime lenses by ZEISS, Cooke S4 sets, and the new Leica Summilux-C primes.

Cocoon is based in Jena, which happens to be where Carl Zeiss set up shop in 1846. These guys are engineers, and anyone who has wrestled with the family’s Thanksgiving turkey electric carving knife trying to cut holes in foam will appreciate their prowess.

Cocoon case interiors are milled as one piece. That means a solid block of foam can be layered as if on a CNC machine. Most other cases are cut in layers and then glued together. Cocoon has calculated foam types and densities that match weight and performance, using special foam to ensure high levels of protection. Their case interiors have a unique, high-tech appearance and make it easier to handle the contents.

Also, instead of guessing how many inches of foam you need to protect your precious products, Cocoon has it all figured out. I haven’t conducted cargo-hold to runway drop tests yet, but I think their engineering will have anticipated that. ZEISS and ARRI are current customers of Cocoon, and I imagine the list will expand rapidly for this exciting new company.